Pakistan possesses an extensive canal network crucial for irrigation, originating from various barrages along its major rivers. These barrages utilize steel gates to regulate water flow. To facilitate the maintenance of these gates and associated structures, Bulkhead Gates (cofferdams) are employed. These gates are engineered to float and be submerged at specific locations to isolate sections of the barrage for maintenance work, both upstream and downstream. M/s DESCON Engineering (Pvt) is currently undertaking a significant project to rehabilitate the gates of the Guddu Barrage.

M/s DESCON Engineering procured the design for an Upstream Bulkhead Gate from an experienced design firm and proceeded with its fabrication in their workshop. During the construction phase, DESCON implemented design modifications to accommodate certain onsite requirements. However, initial testing of the Bulkhead Gate revealed unexpected instability during tilting, ballasting, and de-ballasting procedures. While DESCON attempted to mitigate this using concrete weights, the gate’s operation remained cumbersome throughout the ballasting and de-ballasting sequences.

SOLUTION

- Validated the Weight and Center of Gravity (CoG) data of the Bulkhead gate using the available documentation.

- Conducted an Inclination Test to accurately determine the Displacement/Weight and CoG of the Bulkhead gate.

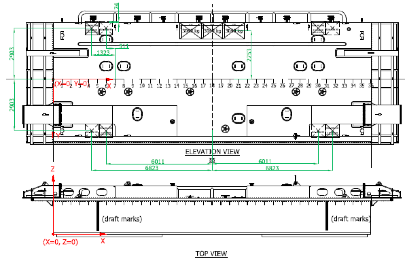

- Developed a software model and simulation of the Bulkhead Gate, incorporating weight data and internal subdivision, to perform hydrostatic and stability analysis. This analysis assessed resultant heel and trim conditions under various loading scenarios during flooding and de-flooding.

- Proposed minimal modifications to the counter-weight/ballast weight to achieve the required trim and heel conditions across different loading states of the Bulkhead Gate, ensuring verification against relevant standards.

- Provided production drawings detailing the proposed modifications.

- Developed a comprehensive ballasting and de-ballasting sequence for the finally recommended configuration of the Bulkhead Gate.

- Validated an improvised ballasting/de-ballasting sequence previously adopted by M/s DESCON through simulation using hydrostatic and stability software.

- Provided an EPESOL Naval Architect for onsite support during the Bulkhead Gate trials.

CONCLUSION:

EPESOL successfully provided a practical solution to adjust the CoG of the Bulkhead Gate, effectively resolving the undesired loll condition without compromising the structural integrity of the floating bulkhead. Through detailed hydrostatic and stability analysis, EPESOL generated comprehensive drawings of all suggested adjustments and provided an updated ballasting and de-ballasting sequence, which was subsequently verified by the client’s project consultant.